Is 3D Printing Material Recyclable?

Are you a fan of 3D printing? Do you wonder if the materials used in this process are recyclable and environmentally friendly? Well, great news! Today we are tackling the hot topic of “Is 3D Printing Material Recyclable?” So grab your cup of coffee or tea and join us on this journey to discover the truth about sustainability in 3D printing. Let’s dive right into it!

What is 3d printing?

3D printing is a manufacturing process where objects are created by depositing layers of material one on top of the other. This process can be used to create objects of any shape or size and is often used for prototyping or creating small batches of custom products.

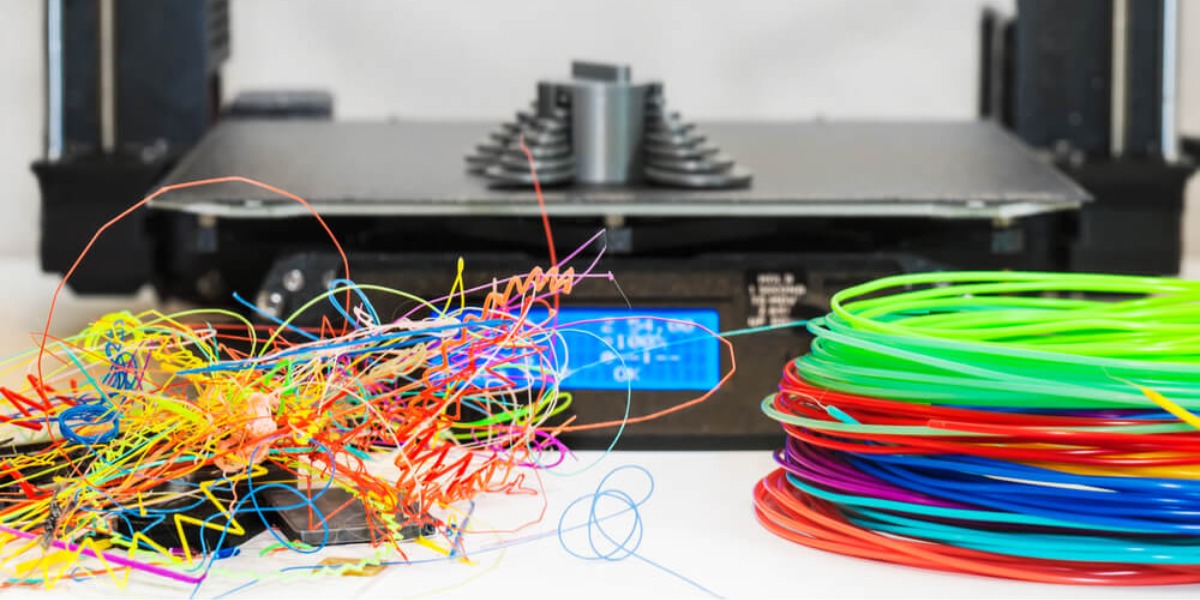

There are a variety of different materials that can be used for 3D printing, including plastics, metals, ceramics, and even food. Most 3D printers use filament – a long strand of material that is fed into the printer – as their primary printing medium. The filament is melted inside the printer and deposited in layers to create the desired object.

3D-printed objects can be recycled just like any other manufactured product. However, because 3D-printed objects are often made from multiple different materials, they may need to be separated before they can be recycled properly.

What materials can be used for 3d printing?

There is a range of materials that can be used for 3D printing, including plastics, metals, ceramics, and composites. Each material has its own unique properties and applications.

Plastics are the most commonly used material for 3D printing. They are lightweight, durable and available in a wide range of colors. Common plastic materials used for 3D printing include ABS (acrylonitrile butadiene styrene) and PLA (polylactic acid).

Metals such as aluminum, stainless steel and titanium can also be used for 3D printing. These materials are strong and heat-resistant, making them ideal for applications such as aerospace engineering and medical implants.

Ceramics such as porcelain and glass can also be 3D printed. These materials are typically used for aesthetic purposes or to create prototypes that cannot be made with other materials.

Composites are another type of material that can be used for 3D printing. These materials combine two or more different substances to create a new material with unique properties. For example, carbon fiber composites are often used in the aerospace industry due to their high strength-to-weight ratio.

Reverse Engineering using 3D Printing in Dubai

Reverse engineering is the process of recreating an existing product or component by analyzing its design and structure. 3D printing technology has revolutionized the reverse engineering process by allowing for the creation of accurate and detailed replicas of existing parts or products.

The C3D printing company is one of the providers that offer reverse engineering services in Dubai. They use advanced 3D scanning technology to capture detailed measurements and data from existing parts, and then use 3D printing technology to produce accurate replicas.

This process can be used in a variety of industries, from aerospace to automotive, and can save time and money compared to traditional manufacturing methods.

What are the benefits of 3d printing?

There are many benefits to 3D printing, including the ability to recycle materials. By recycling materials, you can save money and reduce waste. Additionally, 3D printing can help you create custom products that cannot be made with traditional manufacturing methods.

Best 3D additive manufacturing Company In Dubai

C3D is a 3D printing additive manufacturing company that caters to a wide range of industries. By providing businesses with greater agility, C3D creates value for its clients. As a result, businesses are able to move faster and adapt more easily to changes in their markets. This allows them to stay ahead of their competition and continue growing.

Are there any environmental concerns with 3d printing?

Yes, there are environmental concerns with 3D printing. One of the main concerns is that technology uses a lot of energy and resources to create products. Additionally, 3D printing can produce harmful emissions, depending on the type of filament used.

How to recycle 3d printing material

3D printing is a process of additive manufacturing in which three-dimensional objects are created from a digital file. One of the benefits of 3D printing is that it allows for the recycling of 3D printing material.

In order to recycle your 3D printing material, you will need to first remove any unwanted parts from the object. Once you have removed all of the unwanted parts, you can then shred or grind the object into small pieces. These small pieces can then be melted and reformed into new 3D printing filaments.

There are a few things to keep in mind when recycling your 3D printing material. First, you will need to make sure that all of the pieces are small enough to fit through the opening of your 3D printer.

Second, you will need to make sure that the pieces are free of any contaminants such as dirt or dust. Finally, you will need to ensure that the pieces are meltable. If they are not meltable, they will not be able to be reformed into new filaments.

If you follow these steps, you will be able to recycle your 3D printing material and create new filaments for your 3D printer. This new filament can be used to create new objects, or it can be used to replace old filament in your printer.

Either way, recycling your 3D printing material is a great way to reduce waste and save money on your 3D printing costs. More other catagory post visit check here.